Other products

Mixers

Mixer applies for all mixing applications require varying degrees of both small-scale turbulence and bulk flow. Mixers easily blend highly contaminated fluids high-density or high-viscosity liquids, and liquids with fibrous material.

With a good bulk flow, the contents of the entire tank are set into motion involving in the mixing process. The strength of the bulk flow is, in turn, dependent on the total amount of installed thrust and layout.

Please contact us for Turkish manufacture information!

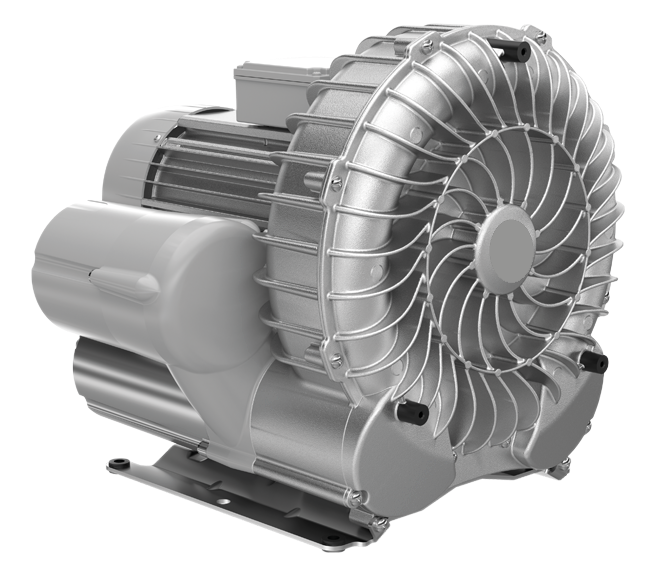

Regenerative blowers

Regenerative blowers have multi-vane impellers that rotate inside its chamber with the use of an electric motor. The impeller rotates inside the blower housing, pulling air in through the inlet, or vacuum side. The impeller then accelerates the air or gas inside the housing until it is fully pressurized, and discharges it through the exhaust outlet, or pressure side.

This blower generates very little noise and comes in a compact package. It is cost-efficient and highly adaptable.

Please contact us for Turkish manufacture information!

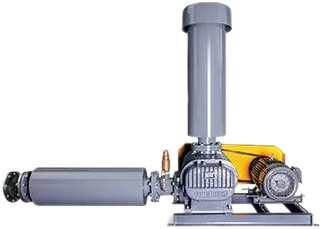

Roots blowers

Roots blower function of sewage treatment is to use air inlet and blast through the bottom air duct to aerate and lift the bottom sediment, and then discharge it through the wastewater pump. The microorganisms in the sewage are oxidized and then achieve the purpose of clear sewage.

Please contact us for Turkish manufacture information!

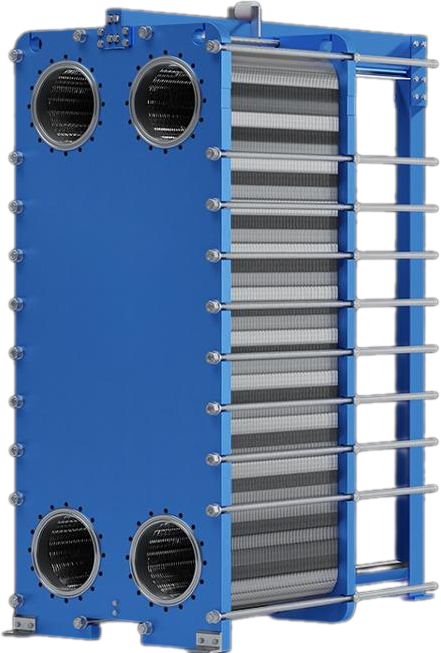

Plate Heat Exchangers (PHE):

Plate heat exchangers are one of the most common types of heat exchanger employed today. It is a type of heat exchanger that uses metal plates to transfer heat between two fluids. This has a major advantage over a conventional heat exchanger in that the fluids are exposed to a much larger surface area because the fluids are spread out over the plates. With a plate heat exchanger, heat cuts through the surface and separates the hot medium from the cold. Thus, heating and cooling fluids and gases use minimal energy levels.

Please contact us for Turkish manufacture information!

Shell and Tube Heat Exchangers (STHE)

A shell and tube heat exchanger (STHE) consists of a series of tubes housed within a cylindrical container known as a shell. All tubes within the shell are collectively termed a tube bundle. Each tube passes through a series of baffles and tube tube stacks.

This simplicity design create exceptionally efficient heat exchange rate. The process of a shell and tube heat exchanger involves the use of a liquid or steam that flows into the shell to heat the tubes.

Please contact us for Turkish manufacture information!